Search This Supplers Products:steel structure buildingprefab houseprefabricated steel structuresteel workshopsteel warehouseprefab Villa

- Home

- About us

- Products

- Steel Structure Warehouse

- Steel Structure Workshop

- Poultry Steel Structure

- Multi-storey Steel Structure

- School Steel Building

- Hospital Steel Structure

- Hotel Steel Building

- Stadium Steel Structure

- Airport Steel Structure

- Train Station Steel Structure

- Light Steel Villa

- Membrane Structure

- Steel Structure Buildings

- Faqs

- News

- Certificate

- Contact us

steel frame building bracing

- group name

- Steel Structure Buildings

- Min Order

- 500 square meter

- brand name

- ZYM steel structure building Manufacturer

- model

- ZYM1

- Nearest port for product export

- Qingdao, Shanghai, Guangdong

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- update time

- Thu, 28 Dec 2023 02:07:39 GMT

Paramtents

Name Indonesia steel structure warehouse workshop

Key word Indonesia steel structure workshop with office

Design 3D max,CAD for steel structure frame

Material Q235,Q345B,SS400 steel structure

Foof Galvanized color sheet or sandwich panel

Wall Galvanized sheet for steel structure workshop

Place of project Indonesia steel structure workshop and warehouse

Delivery time 30 days after steel structure drawing confirmation

Package Steel structure frame pallet for 40HQ container

Application workshop,warehouse,office,commercial bulding,shop

Packging & Delivery

-

Min Order500 square meter

Briefing

Detailed

The ZhengYuanMingTeam Group is a leading international steel structure manufacturers with 20+ years of group experience in prefabricated steel material production.We offer the full range of steel structure products, from steel material to highly engineered building systems, as well as accessories. our products have entered into many foreign countries like the El Salvador,Our full production line offers high-quality products at competitive prices. We pay attention to every little detail to ensure our steel structure more perfect.

| Product name |

steel frame building bracing |

|---|---|

| Brand Name |

ZYM |

| Material |

Steel,Anti-rust paint etc |

| Brand |

ZYM steel frame building bracing Manufacturer |

| Keyword |

cheap steel structure workshop,prefab high-strength steel structure warehouse,Industry Steel Structure Warehouse,Single steel structure warehouse |

| Material |

Q235,Q345B,SS400 steel structure |

| Delivery time |

30 days after steel structure drawing confirmation |

| Certificate |

PHI,TUV,BV,CE etc. |

| Package |

Steel structure frame pallet for 40HQ container |

| OEM&ODM |

YES |

| Application |

prefabricated warehouse,steel structure homes,structure steel fabrication |

| FOB port |

Qingdao Guangdong Shanghai |

| Terms of Payment |

L/C, D/A, Western Union, T/T |

| FOB port |

Qingdao Guangdong Shanghai |

| Processing Service |

Bending, Welding, Cutting, Punching, Pre-assembling, Painting |

| Project Solution Capability |

graphic design, 3D model design, total solution for projects |

| Main Materials |

light steel construction |

| Color |

Request, colorful |

| Design Style |

Modern |

| Characteristics |

Safe foundation, anti-seismic and windproof |

| Sales country |

Kazakhstan,Italy,Greenland,Samoa,Singapore,Serbia and Montenegro |

ZYM After-Sale Service , we will still provide the service after the steel frame building bracing installation.

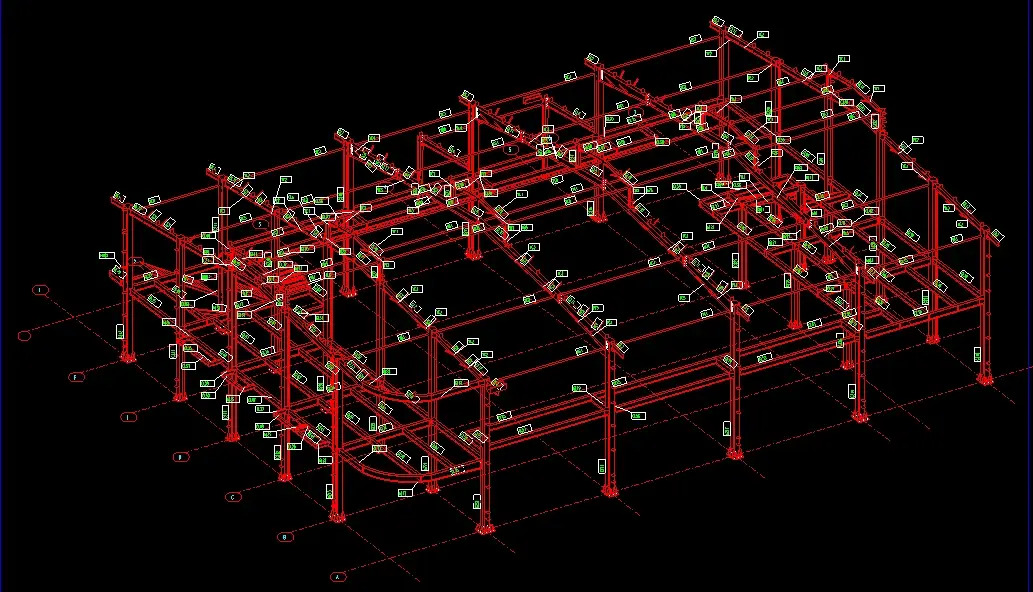

Structural form: Three story steel structure frame engineering

High quality made in China steel frame building bracingBecause The steel structure system has the advantages of light weight, factory manufacturing, quick installation, short construction period, good seismic performance, fast investment recovery and less environmental pollution. Compared with reinforced concrete structures, it is more "high, large and light". steel frame building bracing services FAQs GuideAre you looking for a quick review guide about steel frame building bracingservices?An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding steel frame building bracing services.Let’s continue!

2.What is the seismic resilience of steel frame building bracing?

3.How do the construction time and labor costs for steel frame building bracing compare to traditional building methods?

4.Whats the quality assurance you provided and how do you control quality ?

5.Can steel frame building bracing be relocated or disassembled?

6.What are the design considerations for a steel frame building bracing?

7.steel frame building bracing What factors contribute to the strength and stability of a steel structure building?

8.What safety precautions should be taken when working on a steel structure building?

9.How does the structural integrity of a steel frame building bracing improve safety?

10.How do steel frame building bracing compare in terms of sustainability and green building standards?

1.Are there any limitations on the design possibilities for steel frame building bracing?

We pay attention to user experience and product quality, and provide the best product quality and lowest production cost for cooperative customers. Yes, there are several limitations on the design possibilities for steel structure buildings. These include the availability of steel, the cost of steel, the weight of the steel, the strength of the steel, the size of the steel, the shape of the steel, the welding techniques used, and the fire resistance of the steel. Additionally, local building codes and regulations may also limit the design possibilities for steel structure buildings.

2.What is the seismic resilience of steel frame building bracing?

We maintain a stable growth through reasonable capital operations, focus on industry development trends and cutting -edge technologies, and focus on product quality and safety performance. Steel structure buildings are highly resilient to seismic activity due to their ability to absorb and dissipate energy. Steel structures are able to flex and bend during an earthquake, allowing them to absorb the energy of the seismic waves and reduce the amount of damage that occurs. Steel structures also have a high strength-to-weight ratio, meaning they can withstand large amounts of force without becoming too heavy or bulky. Additionally, steel structures are often designed with seismic bracing and other features to further increase their seismic resilience.

3.How do the construction time and labor costs for steel frame building bracing compare to traditional building methods?

Our steel frame building bracing products undergo strict quality control to ensure customer satisfaction. Steel structure buildings typically require less time and labor costs than traditional building methods. Steel structures are typically pre-engineered and pre-fabricated, meaning that much of the work is done off-site in a factory setting. This reduces the amount of time and labor needed on-site, as well as the amount of waste generated. Additionally, steel structures are often easier to assemble than traditional building methods, which can further reduce labor costs.

4.Whats the quality assurance you provided and how do you control quality ?

Established a procedure to check products at all stages of the manufacturing process - raw materials, in process materials,validated or tested materials, finished goods, etc.

5.Can steel frame building bracing be relocated or disassembled?

We have advantages in marketing and channel expansion. Suppliers have established good cooperative relations, continuously improved workflows, improved efficiency and productivity, and provided customers with high -quality products and services. Yes, steel structure buildings can be relocated or disassembled. Steel structures are designed to be easily dismantled and reassembled, making them ideal for relocation. Steel structures can be disassembled and reassembled quickly and easily, making them a great option for businesses that need to move or expand.

6.What are the design considerations for a steel frame building bracing?

We have a wide range of steel frame building bracing customer groups and establishes long -term cooperative relationships with partners. The countries we provide services include Nigeria. 1. Structural Design: The structural design of a steel structure building should consider the building’s load-bearing capacity, the type of steel used, the size and shape of the steel members, and the connections between the members. 2. Architectural Design: The architectural design of a steel structure building should consider the building’s aesthetic appeal, the type of cladding used, the size and shape of the building, and the overall layout of the building. 3. Fire Protection: The fire protection of a steel structure building should consider the type of fire protection system used, the type of steel used, and the fire resistance rating of the steel. 4. Environmental Considerations: The environmental considerations of a steel structure building should consider the type of steel used, the type of insulation used, and the energy efficiency of the building. 5. Maintenance: The maintenance of a steel structure building should consider the type of steel used, the type of coating used, and the maintenance schedule for the building.

7.steel frame building bracing What factors contribute to the strength and stability of a steel structure building?

We have broad development space in domestic and foreign markets. steel frame building bracing have great advantages in terms of price, quality, and delivery date. 1. Design: The design of a steel structure building is critical to its strength and stability. The design should take into account the loads that the building will be subjected to, such as wind, snow, and seismic forces. 2. Connections: The connections between the steel members are also important for the strength and stability of the building. The connections should be designed to be strong and secure, and should be able to resist the forces that the building will be subjected to. 3. Materials: The materials used in the construction of the steel structure building should be of high quality and should be able to withstand the loads that the building will be subjected to. 4. Foundation: The foundation of the building should be designed to be strong and stable, and should be able to support the weight of the building. 5. Maintenance: Regular maintenance of the steel structure building is important to ensure its strength and stability. This includes inspecting the building for any signs of corrosion or damage, and making any necessary repairs.

8.What safety precautions should be taken when working on a steel structure building?

We have established a good reputation and reliable partnerships within the steel frame building bracing industry. 1. Wear appropriate safety gear, such as hard hats, safety glasses, and steel-toed boots. 2. Use appropriate fall protection equipment, such as safety harnesses and lanyards. 3. Use appropriate tools for the job, such as wrenches, hammers, and saws. 4. Secure all tools and materials to prevent them from falling. 5. Follow all safety protocols and procedures. 6. Inspect the structure for any signs of damage or wear before beginning work. 7. Be aware of your surroundings and watch out for any potential hazards. 8. Use appropriate lifting techniques to prevent injury. 9. Use appropriate scaffolding and ladders to reach higher areas. 10. Disconnect all power sources before beginning work.

9.How does the structural integrity of a steel frame building bracing improve safety?

We are a new steel frame building bracing manufacturer. The structural integrity of a steel structure building improves safety by providing a strong and stable framework that can withstand the forces of nature, such as wind, snow, and earthquakes. Steel is a strong and durable material that is resistant to corrosion and can be designed to meet specific structural requirements. Steel structures are also fire-resistant, which helps to protect occupants in the event of a fire. Additionally, steel structures are often designed with redundancy, meaning that if one part of the structure fails, the other parts can still support the building. This helps to ensure that the building remains standing and safe for occupants.

10.How do steel frame building bracing compare in terms of sustainability and green building standards?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced steel frame building bracing products. Steel structure buildings are highly sustainable and green building standards compliant. Steel is a highly recyclable material, and steel structure buildings can be designed to be energy efficient and to reduce the amount of energy used in their construction. Steel structure buildings are also often designed to be flexible and adaptable, allowing them to be easily modified or expanded as needed. Additionally, steel structure buildings are often designed to be resistant to natural disasters, such as earthquakes and hurricanes, making them a safe and reliable choice for green building standards.