Search This Supplers Products:steel structure buildingprefab houseprefabricated steel structuresteel workshopsteel warehouseprefab Villa

- Home

- About us

- Products

- Steel Structure Warehouse

- Steel Structure Workshop

- Poultry Steel Structure

- Multi-storey Steel Structure

- School Steel Building

- Hospital Steel Structure

- Hotel Steel Building

- Stadium Steel Structure

- Airport Steel Structure

- Train Station Steel Structure

- Light Steel Villa

- Membrane Structure

- Steel Structure Buildings

- Faqs

- News

- Certificate

- Contact us

fabricated steel structure

- group name

- Steel Structure Buildings

- Min Order

- 500 square meter

- brand name

- ZYM steel structure building Manufacturer

- model

- ZYM1

- Nearest port for product export

- Qingdao, Shanghai, Guangdong

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- update time

- Wed, 27 Dec 2023 19:33:07 GMT

Paramtents

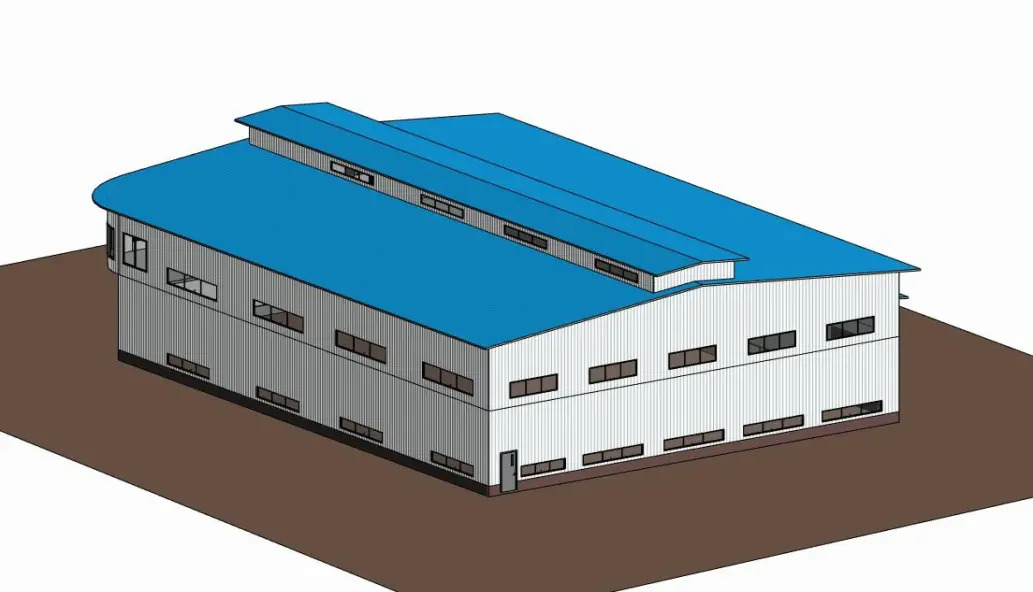

Name Indonesia steel structure warehouse workshop

Key word Indonesia steel structure workshop with office

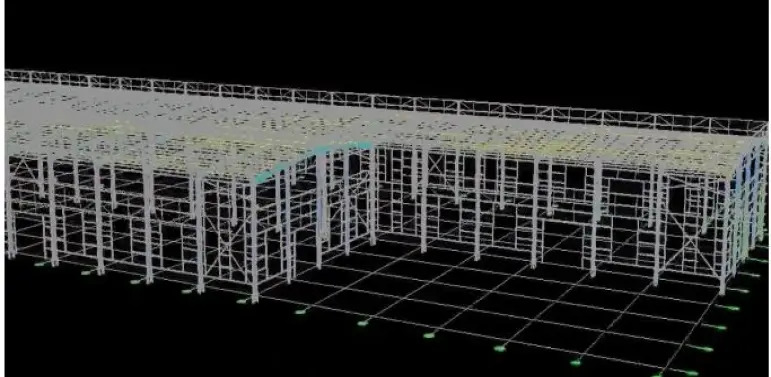

Design 3D max,CAD for steel structure frame

Material Q235,Q345B,SS400 steel structure

Foof Galvanized color sheet or sandwich panel

Wall Galvanized sheet for steel structure workshop

Place of project Indonesia steel structure workshop and warehouse

Delivery time 30 days after steel structure drawing confirmation

Package Steel structure frame pallet for 40HQ container

Application workshop,warehouse,office,commercial bulding,shop

Packging & Delivery

-

Min Order500 square meter

Briefing

Detailed

ZhengYuanming Construction Engineering Co., Ltd.. is a comprehensive building material manufacturer and provider focusing on steel structure construction. such as metal frame cheap steel workshop,multi story steel structure warehouse,lightweight steel structure building,modular steel large span workshop,building with steel structure,steel building warehouse,steel structure installation for workshop etc .Since its establishment, the company has served more than 60 countries and regions in the world. Croatia, and Africa have our partners. Through high-quality products and sincere service, we are well received by customers. We also welcome and look forward to in-depth cooperation with more partners in the world in the future.ZYM has three modern base centers, one center is responsible for design and R&D, one center handles production ,one center is for the sales and service.The group maintains production facilities for high-quality prefabricated steel,steel structure with an annual output of 50,000-60,000 tons of steel structure.

| Product name |

fabricated steel structure |

|---|---|

| Brand Name |

ZYM |

| Model Number |

STEEL - 01 |

| Material |

Steel column base,steel beam etc |

| Brand |

ZYM fabricated steel structure Manufacturer |

| Tolerance |

±1% |

| Keyword |

steel structure prefabricated workshops,light steel structure warehouse supplier,High Quality Prefabricated Workshop,EPS sandwich panel steel structure warehouse,steel structure prefabrication workshop |

| Material |

Q235,Q345B,SS400 steel structure |

| Delivery time |

30 days after steel structure drawing confirmation |

| Certificate |

PHI,TUV,BV,CE etc. |

| Package |

Steel structure frame pallet for 40HQ container |

| Application |

strong prefab steel structure warehouse,steel structure building manufacturer in china,Light Steel Structure Warehouse Workshop,steel frame buildings burnham on crouch,factory steel structure warehouse |

| Processing Service |

Bending, Welding, Decoiling, Cutting, Punching |

| FOB port |

Qingdao Guangdong Shanghai |

| Terms of Payment |

L/C, D/A, Western Union, T/T |

| FOB port |

Qingdao Guangdong Shanghai |

| Processing Service |

Bending, Welding, Cutting, Punching, Pre-assembling, Painting |

| Project Solution Capability |

graphic design, 3D model design, total solution for projects |

| Main Materials |

light steel construction |

| Color |

Request, colorful |

| Design Style |

Modern |

| Characteristics |

Safe foundation, anti-seismic and windproof |

| Sales country |

Denmark,Nigeria,Philippines,Kuwait,Tokelau,Ghana |

Structural form: Three story steel structure frame engineering

ZYM One-Stop Steel Structure Material

High quality made in China fabricated steel structureBecause The steel structure system has the advantages of light weight, factory manufacturing, quick installation, short construction period, good seismic performance, fast investment recovery and less environmental pollution. Compared with reinforced concrete structures, it is more "high, large and light". fabricated steel structure services FAQs GuideAre you looking for a quick review guide about fabricated steel structureservices?An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding fabricated steel structure services.Let’s continue!

2.How does the weight of a steel structure building affect site preparation and construction?

3.How do fabricated steel structure compare in terms of sustainability and green building standards?

4.What design options are available for the exterior aesthetics of a fabricated steel structure?

5.What are the advantages of prefabricated fabricated steel structure?

6.How do the construction time and labor costs for fabricated steel structure compare to traditional building methods?

7.What are the fire safety standards for fabricated steel structure?

8.How does the construction time of a steel structure building compare to traditional methods?

9.Can fabricated steel structure withstand extreme weather conditions?

10.What type of maintenance is required for fabricated steel structure?

11.What is the seismic resilience of fabricated steel structure?

12.What is the maximum height that can be achieved with a ?

13.What is the typical cost of maintenance for a steel structure building?

14.fabricated steel structure What is the average lifespan of a steel structure building?

15.What certifications do your products have?

1.What are the most common applications for fabricated steel structure?

We have a good reputation and image in the industry. The quality and price advantage of fabricated steel structure products is an important factor in our hard overseas market. 1. Warehouses 2. Industrial Buildings 3. Agricultural Buildings 4. Retail Stores 5. Offices 6. Aircraft Hangars 7. Churches 8. Garages 9. Sports Facilities 10. Carports

2.How does the weight of a steel structure building affect site preparation and construction?

We pay attention to employee development and benefits, and provide a good working environment in order to improve the efficiency of employees and improve the quality management of fabricated steel structure products. The weight of a steel structure building affects site preparation and construction in several ways. First, the weight of the steel structure must be taken into account when designing the foundation and other structural elements. The foundation must be designed to support the weight of the steel structure, and the soil must be able to bear the load. Additionally, the weight of the steel structure must be taken into account when designing the crane and other lifting equipment used to move the steel structure into place. Finally, the weight of the steel structure must be taken into account when designing the temporary bracing and other support systems used during construction.

3.How do fabricated steel structure compare in terms of sustainability and green building standards?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced fabricated steel structure products. Steel structure buildings are highly sustainable and green building standards compliant. Steel is a highly recyclable material, and steel structure buildings can be designed to be energy efficient and to reduce the amount of energy used in their construction. Steel structure buildings are also often designed to be flexible and adaptable, allowing them to be easily modified or expanded as needed. Additionally, steel structure buildings are often designed to be resistant to natural disasters, such as earthquakes and hurricanes, making them a safe and reliable choice for green building standards.

4.What design options are available for the exterior aesthetics of a fabricated steel structure?

We should have a stable supply chain and logistics capabilities, and provide customers with high -quality, low -priced fabricated steel structure products. 1. Paint: Steel structures can be painted in a variety of colors to match the surrounding environment. 2. Siding: Steel structures can be clad in a variety of siding materials such as brick, stone, stucco, wood, or metal. 3. Windows and Doors: Steel structures can be fitted with a variety of windows and doors to match the desired aesthetic. 4. Roofing: Steel structures can be fitted with a variety of roofing materials such as metal, shingles, or tiles. 5. Lighting: Steel structures can be fitted with a variety of lighting fixtures to enhance the exterior aesthetic. 6. Awnings: Steel structures can be fitted with awnings to provide shade and protection from the elements.

5.What are the advantages of prefabricated fabricated steel structure?

We continue to invest in research and development and continue to launch innovative products. 1. Cost-Effective: Prefabricated steel structures are cost-effective and can be built quickly, saving time and money. 2. Durability: Steel is a strong and durable material that can withstand harsh weather conditions and is resistant to fire, termites, and other pests. 3. Flexibility: Prefabricated steel structures can be easily modified and adapted to fit any design or purpose. 4. Eco-Friendly: Steel is a recyclable material, making it an environmentally friendly choice for construction. 5. Low Maintenance: Steel structures require minimal maintenance and are easy to clean and repair. 6. Versatility: Prefabricated steel structures can be used for a variety of applications, from residential to commercial and industrial.

6.How do the construction time and labor costs for fabricated steel structure compare to traditional building methods?

Our fabricated steel structure products undergo strict quality control to ensure customer satisfaction. Steel structure buildings typically require less time and labor costs than traditional building methods. Steel structures are typically pre-engineered and pre-fabricated, meaning that much of the work is done off-site in a factory setting. This reduces the amount of time and labor needed on-site, as well as the amount of waste generated. Additionally, steel structures are often easier to assemble than traditional building methods, which can further reduce labor costs.

7.What are the fire safety standards for fabricated steel structure?

Our fabricated steel structure products have competitive and differentiated advantages, and actively promote digital transformation and innovation. 1. Steel structures must be designed and constructed in accordance with the applicable building codes and standards. 2. Fire-resistant materials must be used in the construction of steel structures. 3. Fire-resistant coatings must be applied to steel structures to protect them from fire. 4. Fire-resistant insulation must be installed in steel structures to reduce the spread of fire. 5. Fire-resistant doors and windows must be installed in steel structures to prevent the spread of fire. 6. Fire-resistant sprinkler systems must be installed in steel structures to control the spread of fire. 7. Fire-resistant smoke detectors must be installed in steel structures to detect the presence of smoke. 8. Fire-resistant fire extinguishers must be installed in steel structures to extinguish fires.

8.How does the construction time of a steel structure building compare to traditional methods?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Steel structure buildings typically take less time to construct than traditional methods. Steel structures can be erected in a fraction of the time it takes to build a traditional building, often in as little as half the time. Steel structures are also more cost-effective, as they require fewer materials and labor to construct. Additionally, steel structures are more durable and require less maintenance over time.

9.Can fabricated steel structure withstand extreme weather conditions?

We have flexible production capacity. Whether you are large orders or small orders, you can produce and release goods in a timely manner to meet customer needs. Yes, steel structure buildings are designed to withstand extreme weather conditions. Steel is a strong and durable material that is resistant to wind, rain, snow, and other elements. Steel buildings are also designed to be energy efficient, helping to reduce energy costs in extreme weather conditions.

10.What type of maintenance is required for fabricated steel structure?

We enjoy high authority and influence in the industry and continue to innovate products and service models. Steel structure buildings require regular maintenance to ensure they remain structurally sound and safe. This includes inspecting the building for signs of corrosion, checking for loose or damaged fasteners, inspecting the roof and walls for signs of wear, and inspecting the foundation for signs of settlement or cracking. Additionally, it is important to regularly inspect the building for signs of pests or other infestations, and to check for any signs of water damage.

11.What is the seismic resilience of fabricated steel structure?

We maintain a stable growth through reasonable capital operations, focus on industry development trends and cutting -edge technologies, and focus on product quality and safety performance. Steel structure buildings are highly resilient to seismic activity due to their ability to absorb and dissipate energy. Steel structures are able to flex and bend during an earthquake, allowing them to absorb the energy of the seismic waves and reduce the amount of damage that occurs. Steel structures also have a high strength-to-weight ratio, meaning they can withstand large amounts of force without becoming too heavy or bulky. Additionally, steel structures are often designed with seismic bracing and other features to further increase their seismic resilience.

12.What is the maximum height that can be achieved with a ?

We focus on providing high fabricated steel structure quality products and services. The maximum height of a steel structure building is determined by the strength of the steel used, the design of the building, and local building codes. Generally, steel structures can reach heights of up to 30 stories or more.

13.What is the typical cost of maintenance for a steel structure building?

We pay attention to the transformation of intellectual property protection and innovation achievements. Your OEM or ODM order design we have a complete confidentiality system. The cost of maintenance for a steel structure building can vary greatly depending on the size and complexity of the building. Generally, the cost of maintenance for a steel structure building is between 1-2% of the total cost of the building. This cost includes regular inspections, painting, and repairs.

14.fabricated steel structure What is the average lifespan of a steel structure building?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. The average lifespan of a steel structure building is between 50 and 100 years, depending on the quality of the materials used and the maintenance of the building.

15.What certifications do your products have?

Providing safety and quality steel structure systems, ZYM Team Group has a strong focus on manufacturing all major components of steel structure building ,we have 5 steel structure production lines. ZYM covers an area of more than 50,000 square meters, with excellent equipment, numerical control technology and high degree of automation. Our products are approved by PHI,TUV,BV,CE etc.