Search This Supplers Products:steel structure buildingprefab houseprefabricated steel structuresteel workshopsteel warehouseprefab Villa

- Home

- About us

- Products

- Steel Structure Warehouse

- Steel Structure Workshop

- Poultry Steel Structure

- Multi-storey Steel Structure

- School Steel Building

- Hospital Steel Structure

- Hotel Steel Building

- Stadium Steel Structure

- Airport Steel Structure

- Train Station Steel Structure

- Light Steel Villa

- Membrane Structure

- Steel Structure Buildings

- Faqs

- News

- Certificate

- Contact us

a building made with steel structure

- group name

- Steel Structure Buildings

- Min Order

- 500 square meter

- brand name

- ZYM steel structure building Manufacturer

- model

- ZYM1

- Nearest port for product export

- Qingdao, Shanghai, Guangdong

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- update time

- Wed, 27 Dec 2023 18:29:54 GMT

Paramtents

Name Indonesia steel structure warehouse workshop

Key word Indonesia steel structure workshop with office

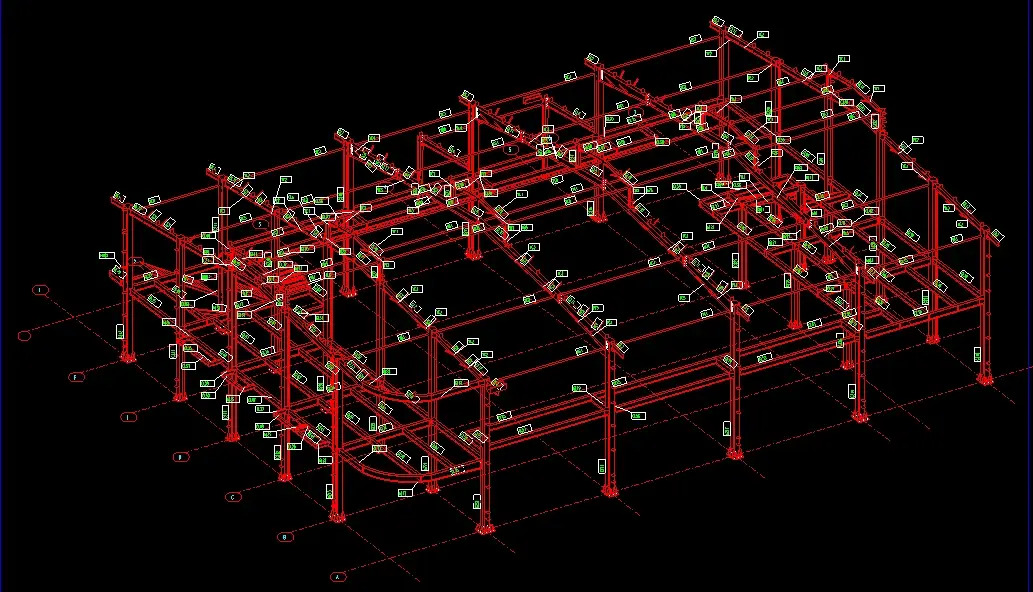

Design 3D max,CAD for steel structure frame

Material Q235,Q345B,SS400 steel structure

Foof Galvanized color sheet or sandwich panel

Wall Galvanized sheet for steel structure workshop

Place of project Indonesia steel structure workshop and warehouse

Delivery time 30 days after steel structure drawing confirmation

Package Steel structure frame pallet for 40HQ container

Application workshop,warehouse,office,commercial bulding,shop

Packging & Delivery

-

Min Order500 square meter

Briefing

Detailed

ZhengYuanming Construction Engineering Co., Ltd. of BY Group is a comprehensive industrial group integrating for steel structure design, manufacture and installation. We have estabulished over 20 years. Our factory is covering about 126 ,5 60 square meters. Main products: Fabricate heavy steel structure workshop,workshop prefabricated ,China steel workshop,modern light steel structure warehouse workshop,prefab steel structure warehouse for rice,Industrial big steel structure warehouse,steel structure workshop Modern appearanceProduction Capacity:ZYM has three modern base centers, one center is responsible for design and R&D, one center handles production ,one center is for the sales and service.The group maintains production facilities for high-quality prefabricated steel,steel structure with an annual output of 50,000-60,000 tons of steel structure.Export experiences: products have been exported to over 80countries. such as: Czech Republic.Certificate: Our products are approved by PHI,TUV,BV,CE etc.Engineers team: We have over 30 engineers. We Can make design according to Clients requirement. We fabricate the products according to the clients design.We will consider all the technical information requirements and fabrication requirements from our clients When we make the design.

| Product name |

a building made with steel structure |

|---|---|

| Brand Name |

ZYM |

| Model Number |

STEEL - 01 |

| Material |

like steel pillar,Low alloy steel plate,studs etc |

| Brand |

ZYM a building made with steel structure Manufacturer |

| Tolerance |

±1% |

| Keyword |

Construction modern design steel structure workshop,large prefabricated steel structure workshop,workshop structural steel,steel frame agricultural building,high-quality steel structure warehouse |

| Material |

Q235,Q345B,SS400 steel structure |

| Delivery time |

30 days after steel structure drawing confirmation |

| Certificate |

PHI,TUV,BV,CE etc. |

| Package |

Steel structure frame pallet for 40HQ container |

| Application |

famous steel structure building,single span steel structure warehouse,gable frame steel structure warehouse |

| Processing Service |

Bending, Welding, Decoiling, Cutting, Punching |

| FOB port |

Qingdao Guangdong Shanghai |

| Terms of Payment |

L/C, D/A, Western Union, T/T |

| FOB port |

Qingdao Guangdong Shanghai |

| Processing Service |

Bending, Welding, Cutting, Punching, Pre-assembling, Painting |

| Project Solution Capability |

graphic design, 3D model design, total solution for projects |

| Main Materials |

light steel construction |

| Color |

Request, colorful |

| Design Style |

Modern |

| Characteristics |

Safe foundation, anti-seismic and windproof |

| Sales country |

Guadeloupe,Lesotho,Morocco,Suriname,Tanzania |

High quality carbon structural steel and alloy structural steel

ZYM After-Sale Service , we will still provide the service after the a building made with steel structure installation.

ZYM provide the integrated solutions for our clients . After the steel structure design , we arrange the steel Fabricate heavy steel structure workshop,workshop prefabricated ,China steel workshop,modern light steel structure warehouse workshop,prefab steel structure warehouse for rice,Industrial big steel structure warehouse,steel structure workshop Modern appearance . In the process , we provide the best quality steel structure and the quality is approved a building made with steel structure services FAQs GuideAre you looking for a quick review guide about a building made with steel structureservices?An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding a building made with steel structure services.Let’s continue!

2.What are the fire safety standards for a building made with steel structure?

3.a building made with steel structure What is the average lifespan of a steel structure building?

4.Can a building made with steel structure be customized to fit specific design requirements?

5.What type of steel is used in the construction of a building made with steel structure?

6.How does the weight of a steel structure building affect site preparation and construction?

7.What safety precautions should be taken when working on a steel structure building?

8.What type of maintenance is required for a building made with steel structure?

1.Can a building made with steel structure be relocated or disassembled?

We have advantages in marketing and channel expansion. Suppliers have established good cooperative relations, continuously improved workflows, improved efficiency and productivity, and provided customers with high -quality products and services. Yes, steel structure buildings can be relocated or disassembled. Steel structures are designed to be easily dismantled and reassembled, making them ideal for relocation. Steel structures can be disassembled and reassembled quickly and easily, making them a great option for businesses that need to move or expand.

2.What are the fire safety standards for a building made with steel structure?

Our a building made with steel structure products have competitive and differentiated advantages, and actively promote digital transformation and innovation. 1. Steel structures must be designed and constructed in accordance with the applicable building codes and standards. 2. Fire-resistant materials must be used in the construction of steel structures. 3. Fire-resistant coatings must be applied to steel structures to protect them from fire. 4. Fire-resistant insulation must be installed in steel structures to reduce the spread of fire. 5. Fire-resistant doors and windows must be installed in steel structures to prevent the spread of fire. 6. Fire-resistant sprinkler systems must be installed in steel structures to control the spread of fire. 7. Fire-resistant smoke detectors must be installed in steel structures to detect the presence of smoke. 8. Fire-resistant fire extinguishers must be installed in steel structures to extinguish fires.

3.a building made with steel structure What is the average lifespan of a steel structure building?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. The average lifespan of a steel structure building is between 50 and 100 years, depending on the quality of the materials used and the maintenance of the building.

4.Can a building made with steel structure be customized to fit specific design requirements?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market. Yes, steel structure buildings can be customized to fit specific design requirements. Steel structure buildings are highly customizable and can be designed to meet the exact needs of the customer. Steel structure buildings can be designed to fit any size, shape, or style, and can be customized with a variety of features such as windows, doors, insulation, and more.

5.What type of steel is used in the construction of a building made with steel structure?

We adhere to the principle of integrity and transparency, and establish long -term relationships with partners, and we attach great importance to this detail. The most common type of steel used in the construction of steel structure buildings is mild steel, also known as low carbon steel. Other types of steel that may be used include high-strength steel, stainless steel, and weathering steel.

6.How does the weight of a steel structure building affect site preparation and construction?

We pay attention to employee development and benefits, and provide a good working environment in order to improve the efficiency of employees and improve the quality management of a building made with steel structure products. The weight of a steel structure building affects site preparation and construction in several ways. First, the weight of the steel structure must be taken into account when designing the foundation and other structural elements. The foundation must be designed to support the weight of the steel structure, and the soil must be able to bear the load. Additionally, the weight of the steel structure must be taken into account when designing the crane and other lifting equipment used to move the steel structure into place. Finally, the weight of the steel structure must be taken into account when designing the temporary bracing and other support systems used during construction.

7.What safety precautions should be taken when working on a steel structure building?

We have established a good reputation and reliable partnerships within the a building made with steel structure industry. 1. Wear appropriate safety gear, such as hard hats, safety glasses, and steel-toed boots. 2. Use appropriate fall protection equipment, such as safety harnesses and lanyards. 3. Use appropriate tools for the job, such as wrenches, hammers, and saws. 4. Secure all tools and materials to prevent them from falling. 5. Follow all safety protocols and procedures. 6. Inspect the structure for any signs of damage or wear before beginning work. 7. Be aware of your surroundings and watch out for any potential hazards. 8. Use appropriate lifting techniques to prevent injury. 9. Use appropriate scaffolding and ladders to reach higher areas. 10. Disconnect all power sources before beginning work.

8.What type of maintenance is required for a building made with steel structure?

We enjoy high authority and influence in the industry and continue to innovate products and service models. Steel structure buildings require regular maintenance to ensure they remain structurally sound and safe. This includes inspecting the building for signs of corrosion, checking for loose or damaged fasteners, inspecting the roof and walls for signs of wear, and inspecting the foundation for signs of settlement or cracking. Additionally, it is important to regularly inspect the building for signs of pests or other infestations, and to check for any signs of water damage.