Search This Supplers Products:steel structure buildingprefab houseprefabricated steel structuresteel workshopsteel warehouseprefab Villa

- Home

- About us

- Products

- Steel Structure Warehouse

- Steel Structure Workshop

- Poultry Steel Structure

- Multi-storey Steel Structure

- School Steel Building

- Hospital Steel Structure

- Hotel Steel Building

- Stadium Steel Structure

- Airport Steel Structure

- Train Station Steel Structure

- Light Steel Villa

- Membrane Structure

- Steel Structure Buildings

- Faqs

- News

- Certificate

- Contact us

China high rise large span Steel Structure Warehouse workshop Factory manufacture With CE Certification

- FOB Price

US $30.0500 - 20000 square meter

- group name

- Steel Structure Workshop

- Min Order

- 500 square meter

- brand name

- ZYM steel structure building Manufacturer

- model

- ZYM-01

- Nearest port for product export

- Qingdao, Shanghai, Guangdong

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- update time

- Thu, 07 Dec 2023 14:49:12 GMT

Paramtents

Name China Steel Structure Warehouse workshop with CE

Key word China steel warehouse workshop manufacture with CE

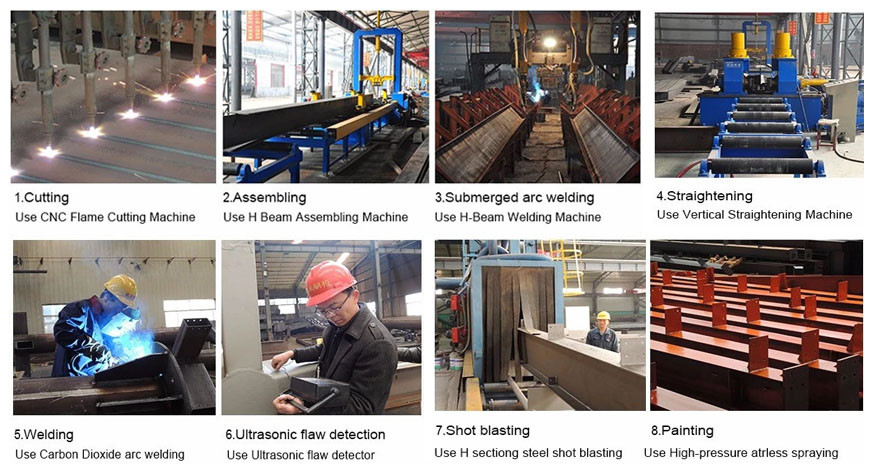

Material Q235,Q345B,SS400,H type hot rolled steel

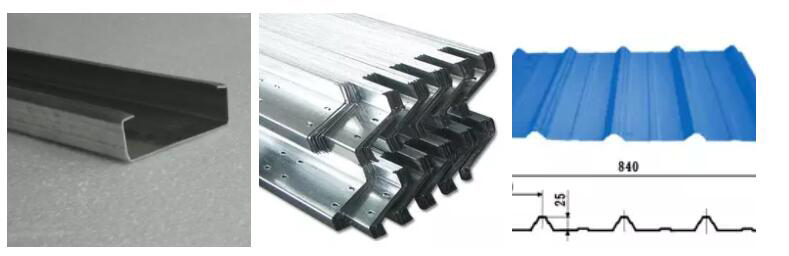

roof of steel structure workshop Galvanized color sheet or sandwich panel

wall of steel structure workshop Galvanized color sheet or sandwich panel

steel structure workshop door and window Aluminium alloy and PVC

Application workshop,warehouse,office,hotel,commerical,school

Certification CE certification,ISO certification

delivery time 30 days after steel structure design confirmed

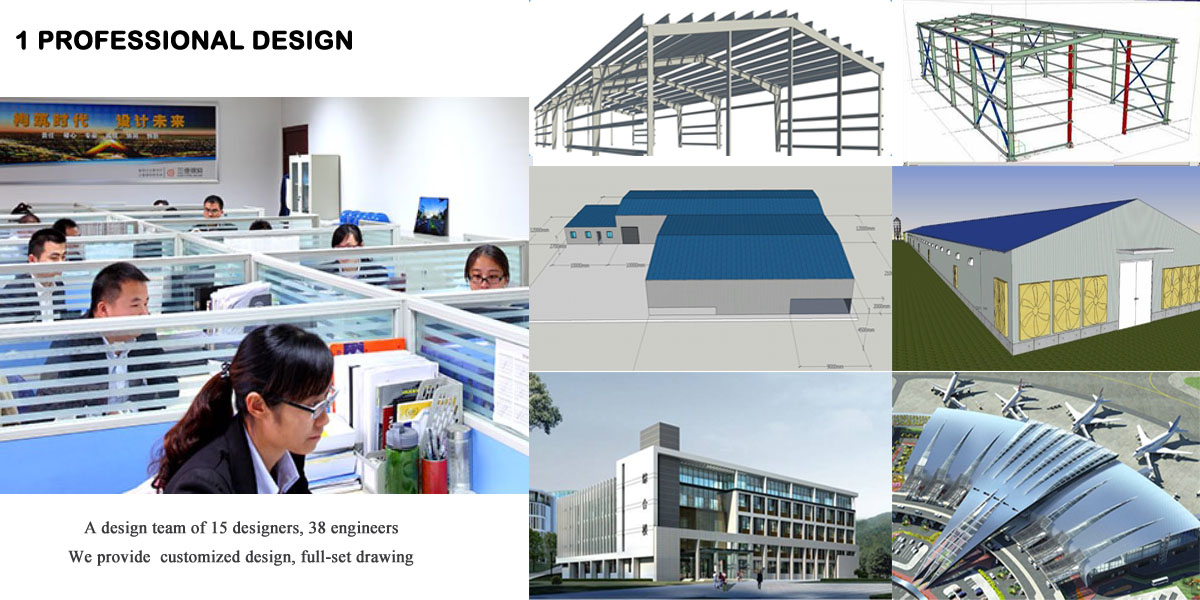

steel structure design softwaree CAD,3D3S,3DMX,TEKLA

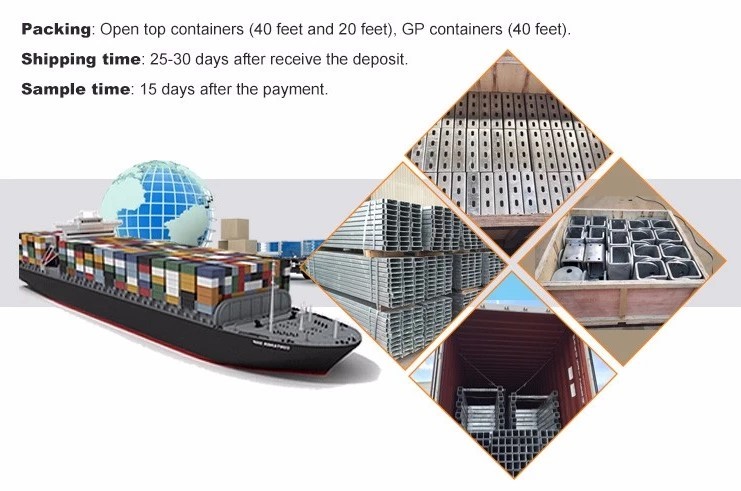

Packging & Delivery

-

Min Order500 square meter

Briefing

Detailed