Search This Supplers Products:steel structure buildingprefab houseprefabricated steel structuresteel workshopsteel warehouseprefab Villa

- Home

- About us

- Products

- Steel Structure Warehouse

- Steel Structure Workshop

- Poultry Steel Structure

- Multi-storey Steel Structure

- School Steel Building

- Hospital Steel Structure

- Hotel Steel Building

- Stadium Steel Structure

- Airport Steel Structure

- Train Station Steel Structure

- Light Steel Villa

- Membrane Structure

- Steel Structure Buildings

- Faqs

- News

- Certificate

- Contact us

Prefab Steel Structure for Mauritius International Airport

- group name

- Airport Steel Structure

- Min Order

- 1 piece

- brand name

- ZYM steel structure building Manufacturer

- Nearest port for product export

- Qingdao, Shanghai, Guangdong

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- update time

- Wed, 10 Jul 2019 10:53:52 GMT

Packging & Delivery

-

Min Order1 piece

Briefing

The design of the steel airport is modern.The light weight is simple and the construction period is short.

Detailed

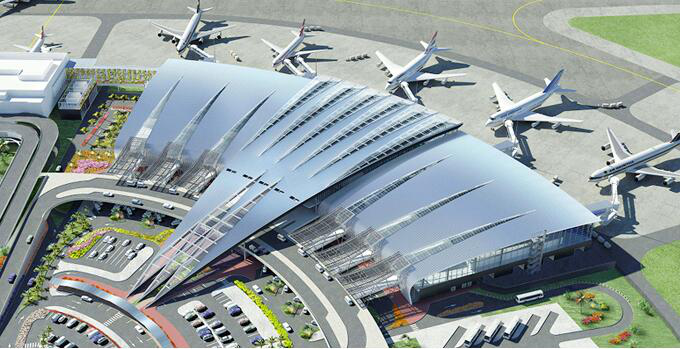

Mauritius Airport Steel Structure

Mauritius Airport Steel Structure is the international airport of the Republic of Mauritius.

The airport is located in the Dagang District of Mauritius, 48 kilometers from the capital city of Port Louis.

It is a large airport in the country , which is a base and hub airport for Mauritius Airlines.

Our company undertook the design of the steel structure .

According to the requirements of Party A, all the nodes are bolted.

The I-shaped steel structure adopts the L connecting piece, and the cutting welding is prohibited on the spot.

There are more than 16,000 pieces of components and 8,500 specifications and models with a total weight of

more than 200 tons.

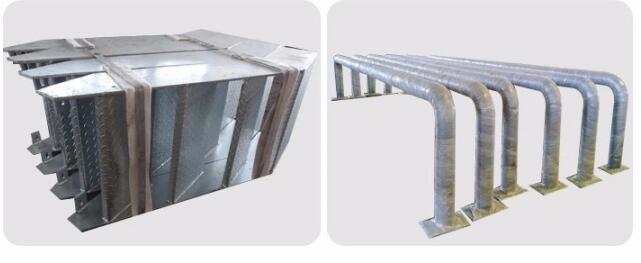

Steel Structure Manufacturing

In the production process, we use the company's unique CNC three-dimensional drilling machine.

The drilling accuracy is 0.5mm, and the L-shaped folding parts are all realized by CNC drilling machine

and CNC bending machine, realizing factory production.

Installation

During the whole process of guiding the installation process, there is no gas cutting and electric welding used

in one place, which shorten the installation time of the whole project by 20% compared with the original plan.

It fully reflects the advantages of factory standardization and is highly recognized by customers.

For further information feel free to contact us